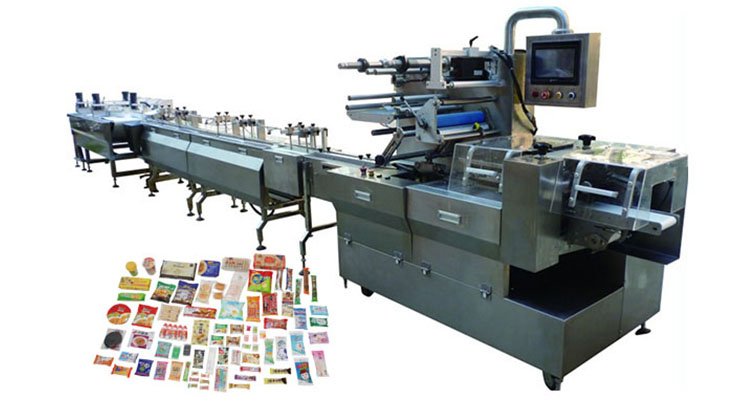

1. Two sets of servo motors. One drives chain conveyor and end sealer, another drives film and long sealer.

2. PLC+HMI components. Bi-lingual (Chinese and English) instructions. Packing speed, length, temperature, control method can by chosen through HMI by numbers.

3. Double tracking method. Photo-sensor working together with servo system can realize automatic controlling according to the color code on the film, to make sure the cutting accuracy.

4. Safety alert and failure alert will be shown on HMI.

5. The design of the machine is a global standard appearance.

6. It can be connected to production lines of different capabilities to realize synchronism.

7. Compatible with multi film structures. The thinnest film can be 0.02-0.1mm.

8. The critical components of electrical system is Japanese made.

Electrical control cabinet

9. 220V electrical heating system, accurate temperature contolling.

10. Color code detection system. Any errors on color code deviation, film misalignment and settings of photo-sensor switching can be shown.

11. Allocation of sealing jaw when stopping to eliminate melting problem of cross seal jaw and film when the machine is stopped.

12. Working platform and packing equipment are adjustable to pack multi dimension bags.

13. Customer can choose different knifes like straight line knife and wave line knife.

14. Code date mechanism with different fonts is optional.

15. Dimension of the machine (L*W*H):

Packing machine 5000*1000*1700mm

16. Power: 220V 4.5KW.

17. Speed: 20--250pbm.

18. Weight : 1000kg